Read Online Walking the Design for Six SIGMA Bridge with Your Customer - Carl Cordy file in PDF

Related searches:

Amazon.com: Walking the Design for Six Sigma Bridge with Your

Walking the Design for Six SIGMA Bridge with Your Customer

Walking the Design for Six Sigma Bridge with Your Customer

Design for Six Sigma (DFSS): the Keys to the Power of Six

Design Thinking for the Legal Profession Ark Group

10 Beautiful Design Ideas for Walk-In Showers

BATS: The Basics of Bridge Design HowStuffWorks

Walking Across the Manhattan Bridge

How Long It Takes to Walk the Brooklyn Bridge

18 Pedestrian Bridges & Footbridges with Amazing Designs Architectural Digest

Singapore Has New Design for Pedestrian Bridge Architectural Digest

Take the Sydney Harbour Bridge Walk

Design for Six Sigma - Wikipedia

Design For Six Sigma (DFSS)

Design For Six Sigma - YouTube

Bridge - iSixSigma: Six Sigma Resources for Six Sigma Quality

The Ultimate Guide to Six Sigma - Six Sigma Daily

(PDF) The evolution of Six Sigma - ResearchGate

The Five Must-Know Phases of a Six Sigma Project Using the

The 5 Deliverables of Six Sigma Define Phase

Design for Lean & Six Sigma (DFLSS) - cpspoly.com

DMAIC: The Complete Guide to Lean Six Sigma in 5 Key Steps

Telling the Difference: Six Sigma, Lean, or Kaizen – 6Sigma.com

Analyze: understand where the problems in your process lie the analysis step is where we have to dig in deep into the existing processes and work out the root causes of the problems.

Although this online six sigma training program is the copyrighted intellectual property of international six sigma institute™, we wanted to make these materials freely accessible for everybody. We believe that only by sharing our expertise we can best serve for six sigma professionals and for the further development of six sigma domain.

The lean six sigma program has enabled me to change my role at work and helped me earn a new title! i look forward to continuing on to the black belt program and to furthering my career. Omid aslani, mba, lean six sigma black belt, chief product and experience officer (cpxo) at emerios.

The average person spends 12,000 hours of their life in the shower. If you're going to spend that much time in one room, you might as well make it as beautiful and inviting as possible.

Advertisement if you're going to build a bridge, you'll need some help from bats -- not the furry, winged mammals that so often live beneath bridges, but the key structural components of bridge construction: beams, arches, trusses and suspe.

Six sigma tools such as a matrix, doe (design of experiments), qtc (quality to control) and regression analysis are used while creating solutions to improve the situation. The statistical solution needs to be converted into a practical one during this ‘improve’ phase.

View the full introductory course for free which includes a modefrontier case study.

Six sigma team leaders also use project management tools, such as gantt charts, and team engagement tools, such as brainstorming and nominal group technique. Six sigma resources you can also search articles� case studies� and publications for six sigma resources.

Industries, six sigma doesnt remove the need for experienced leadership, and it doesnt negate the importance of intuition in any process. Instead, six sigma works alongside other skills, experience, and knowledge to provide a mathematical and statistical foundation for decision making.

We help businesses of all sizes operate more efficiently and delight customers by delivering defect-free products and services. Isixsigma is your go-to lean and six sigma resource for essential information and how-to knowledge.

The definition of six sigma is almost as varied as that of innovation. The dumbing down of six sigma is real, and six sigma does not mean the same thing today for many companies as it was originally intended. According to mikel harry, a legitimate founder of six sigma, six sigma was designed and introduced to generate breakthrough improvement.

The data collected in a lean six sigma project can often be used to support both lean analysis and six sigma analysis. The reliance on data helps to ensure that the true root cause is identified. Both are applied using improvement projects that typically will be implemented by a small cross-functional team.

It is a business process management method related to traditional six sigma and is used in many industries, like finance, marketing, basic engineering, process industries, waste management, and electronics.

Space-savvy strategies, organizational systems, and repurposed furnishings make small walk-in closets function at full capacity. Space-savvy strategies, organizational systems, and repurposed furnishings make small walk-in closets function.

Final process sigma requires operational definitions from implementation plan. The implementation plan is not only used in dmaic but is also used in design for six sigma or the v for verify found in dmadv. There are five elements used to successfully create an implementation plan.

Walking the design for six sigma bridge with your customer: cordy, carl: 9781543454765: books - amazon.

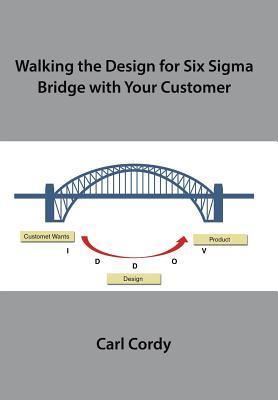

The dmadv project methodology, known as dfss (design for six sigma), features five phases: define design goals that are consistent with customer demands and the enterprise strategy. Measure and identify ctqs (characteristics that are critical to quality), product capabilities, production process capability, and risks.

When most people ask about what is gemba walk, they are usually referring to manufacturing since this is where is more often to hear about this term. So, whenever you hear or read this, this only means that the gemba is the factory floor. Learn more about the problem-solving strategy in lean six sigma.

The six sigma design always emphasizes that success means a win-win situation for both businesses and customers. Clients get the best products and services and the companies get a good profit. Contrary to popular belief, passable goods and services aren’t going to generate the revenue a company needs.

Design for six sigma emerged from the six sigma and the define-measure-analyze-improve-control (dmaic) quality methodologies, which were originally developed by motorola to systematically improve processes by eliminating defects.

Provides lean six sigma related services, as well as design for six sigma, reliability, agile and quality management consulting. The most recent mandates include consulting and training in healthcare, public services, financial services, manufacturing, and supporting start-ups.

If you’re just beginning to research six sigma and what it can do for your company, you’ll quickly realize that six sigma daily is a great source for beginning and intermediate six sigma information. We’ve put together the best resources to help guide you through the learning process as you discover the ins-and-outs of six sigma.

Furthermore, your mastery of six sigma depends on belt color, as different belts require different levels of training. Yellow belts, for instance, have a basic understanding of six sigma and can conduct simple data analysis. Master black belts, on the other hand, are just that – masters of six sigma knowledge and technique.

Modapts excel template for time and motion analysis modular arrangement of predetermined time standards. This modapts template automates the analysis of time and motion to develop reliable production standards on assembly lines.

This is the most commonly asked six sigma interview questions – six sigma (6σ) is a set of techniques and tools for process improvement. This data-driven and disciplined methodology can be used in any process, from manufacturing to transactional and from product to service.

Read walking the design for six sigma bridge with your customer by carl cordy available from rakuten kobo. Besides providing a technical overview of design for six sigma, this is a text that goes the extra step beyond in presen.

Design for six sigma (dfss) is a methodology of improvement that helps businesses create new products or services at a high level of quality. The technique aims to meet the needs of customers and utilize the company’s capability as much as possible during the original development of a process.

A legal lean sigma® black belt and a certified six sigma green belt, catherine is the ceo and a founder of the legal lean sigma institute, which offers consulting and the first and only process improvement and project management certifications, courses, and workshops designed specifically for the legal profession.

The need to adapt six sigma for design projects at� ge gave rise to design for six sigma (dfss). The objective of dfss is to design products, services and� processes that are six sigma capable.

The first point that we need to talk about when discussing the six sigma define phase is defining the problem statement and goal by the project team members. The primary purpose of the six sigma define phase is to ensure the project team is focusing on the feasible business problem or pain area.

The six sigma methodology – define, measure, analyze, improve, control, or dmaic – is known for its ability to eliminate problems resulting from variability in manufacturing, engineering and transactional processes. There will be those times, though, when no improvement will enable an existing process to meet customer expectations.

This course is a green design for lean and six sigma class to train students how to achieve breakthrough improvements in new product design, quality, reliability and total cost reductioneach module. Will introduce new material that will prepare the student for the projects to be completed.

Six sigma focuses on examining a process to find errors that are leading to defects in the product or service. The usual goal is to reduce variability and promote consistency.

Being unclear on the problem your lean six sigma project is solving can happen to anyone, even the most seasoned lean six sigma black belts. You may get so caught up in working on a project and focusing on the details that one day you find the validity of the project comes into question.

Post Your Comments: